Forum Replies Created

-

AuthorPosts

-

Hi David,

can you link Thor ros packages?I am working on ROS intigration as well. And i actually use Angels Hardware.I do not see a prob to do so.But for sure to implement thor in ros there are some custom ROS node needed. ;I am working in ROS indego. And have put the Ardurino board to an Intel edison via serial line.On Intel Edison i have ros runnning. On Ardurino GRBL FW.

Im working on URDF config actually. To simulate Thor in ROS. The will programm the needed nodes to attach ROS to grbl.CU Oliver

Hi Angel,

i have seen you have already updated you GRBL FW. with cpumaping. Great thx.

CU Oliver.Yes it is working.I havend tested all axxis but 2 had worked i guess the other will work too.

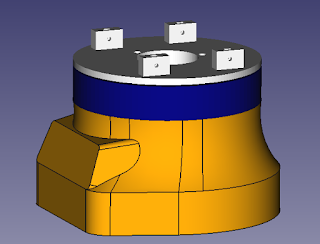

I am working on a new thor base to integrate elektronics. Without an external compartment,I had probs with my printer. The temperature sensor of the hot end was broken, twice. and finally i had a nozzle jam. ;Cheap china stuff. :-(But tonight it looks good printer is back online.I use an ardurino mega and will connect thor pcb directly.Will what i can get done this weekend. The next two weeks i am at ;rehab cente ;with my son. ;So Thor must wait a little. I am 100% sure Thor will work as soon i bring all parts together. ;

CU Oliver ;Hi Wilmer,

welcome. 🙂Hi Adam,

i have printed Thor complete in ABS. The parts are awesome strong.I guess if some joints are made i bit stronger constructed bearing holders. It will last like a tank.CU Oliver.

Welcome Adam,

cool Idea upscaling Thor.So Thor will maybe get i little more payload 🙂CU Oliver

Hi Angel,

i got all parts today. Will solder pcb’s this weekend.

Will see if i get any trouble.

Angel i thought about bringing all elektronic parts in the empty art3.But thors Stepper board will not within one or two milimeters.Maybe it is possible to design smaller boards.So it will have less cabeling and also no extra compartment for electronics except for a power supply ;is possible.

CU Oliver ;Hi Jamie,

as far as i know no one did. I have printed it in a prusaI3. Which is not the tallest printer.Printing this part of thor was fine. I have printed it without support for the roof.My printer has a housing i am unsing ABS a 0.4 nozzle and ABS slurry to glue the part on the glas plate while printing.Temperature bed 110 and nozzle 240.

Only the 90 degrees overhang, where supported.I am not 100% satisfied with my print since the new cooling slots in the roof brought me a litle ;warping during print and the printer motors had lost some steps. I had luck to rehome and restart print at this point.

Maybe someone else is able to recomment a ;better solution.CU Oliver

Hi danny,

looks good.That will mean Thor will have an endless axxis 1 and 6. ;

CU OliverHi,

i thought it is o good idea to add i pi with ros installed on it.There are libs available to communicate with ardurino and also to calculate kinematics.Pi will have enough processing power to do so.Will see if i get it done this way. Actually still printing. (I am at the 3 axxis.)

I have orderd thor stepper boards from pcbway they will come this week. ;

All other hardware is in place. As soon i get the boards i will start comissioning electronics and generate software.

CU OliverHi William,

not a bad solution. I am not certain how much realtime it is possible to get directly out of a pi.I my company we use kuka robots. Everthing runs on a single pc with vxworks and windows.

I would believe a pi with an axis controller software on it and another pi with an userinterface could also be nice.And 99.9 % realtime. It is worth to test it. 🙂

CU OliverHi Danny, looks promissing.

did you finalice you Software?I have played with your rob_gui it realy cool.Did you post your source code on github or will it not be opensource ?CU Oliver

Hmm looks alike i should calibrate y and x on my printer.All diameters what i have printed yet are almost the same size to small.The outer diameter is also missing something like 1 mm.And the 0.5 could be something like overextruding. ;

So i would recomment to all other users to fine calibrate the printer bevor start printing. ;Otherwise the larger holes like the 110mm bearing in bastop are out of ;tollerance and the bearing ist not mountable without rework.

Cause i am in the middle of printing base and art2 i will test this later.Otherwise all my parts are not be alligned at the outer shell. ;

CU ;Oliver -

AuthorPosts