Forum Replies Created

-

AuthorPosts

-

Hi Mohamed!

I think I found a commit with the gerber files of the first version of the ControlPCB (single layer): https://github.com/AngelLM/Thor/tree/a45186dc852a9880c0d2699d243ae8d5bddf9bb3/electronics

Check it out and tell me if that was what you were looking for 😉

Hi Colin!

Thanks your words, I’m glad you like it!

Regarding the Asgard issue, have you been able to execute a Gcode command via Arduino IDE Serial Console? (More info about this in Firmware Documentation)

If that is not the problem, maybe there is something wrong with Asgard´s python code… And I´m pretty sure that would be this line:import serial_port_finder as spf

I´ll take a look to it meanwhile!-

This reply was modified 3 years, 9 months ago by

Angel LM.

Angel LM.

The width of the GT2 Pulleys should be 6mm 😉

Hola Iván,

Habría dos maneras de hacerlo. Por un lado, generar un archivo .gcode y ejecutarlo con el Universal Gcode Sender.

Por otro lado, se puede programar un script en python que envíe por el puero serie las instrucciones de movimiento (un ejemplo de ésto último puedes encontrarlo en este repo)

Espero que sea de ayuda!—-

Hello Ivan,

There would be two ways to do it. On the one hand, generating a .gcode file and running it with Universal Gcode Sender.

On the other hand, you can program a python script that sends through the serial port the movement instructions (an example of this can be found in this repo).

I hope it helps!“The first variant probably allows to connect the male PCB connector directly into the Arduino female connector?”

Yeah, you are right!It doesn’t matter the direction as long as the connections match with this diagram would be ok.

-

This reply was modified 3 years, 9 months ago by

Angel LM.

Angel LM.

I’m glad you found the solution 😉

If you have any other questions, feel free to ask!I see, could you please share your $$ settings?

You can view them by sending$$via Serial to the Arduino.PD: Sorry for the late reply!

Hi EleKoPhi!

Could you please share your $$ settings? To see the these settings just send

$$via Serial to the Arduino and it should send them back to you.No problem with that! The purpose of this forum is to answer this kind of questions 🙂

The main disadvantage when lifting more weight is the strength of the motors. Specifically of the motors of the last 3 joints. While it is true that the motors of joints 1, 2 and 3 are not very strong, the small motors of joints 5 and 6 are not capable of supporting a heavy load.

Yes, I was referring to the interchangeable gripper as the tool.

Don’t hesitate to ask any questions you may have!

It will be a pleasure! I will need a photo of your Thor and (optional) a link to a blog of the project or something similar 🙂

Hi! The reference of the fuse I used for the Control PCB Board is MF-R700 which is a Polymeric PTC Resettable Fuse 30V 7A.

Hope it helps!

Hi Mendy,

750g refers to 750g minus the weight of the tool.

Anyway, I did that test quite some time ago and I am not sure that the value is correct, it will be around that value, but I would not take it as a reference.Hope it helps!

Hi jose,

If you mean the PCB schematic, is already available at Downloads section, (Gerbers and KiCad source files) or if you prefer GitHub: ThorControlPCB repository.

Hope it helps!

I have added yout entry to the Worldwide Section 🙂

When you have that article published, let me know so I can link it 😉Great job!

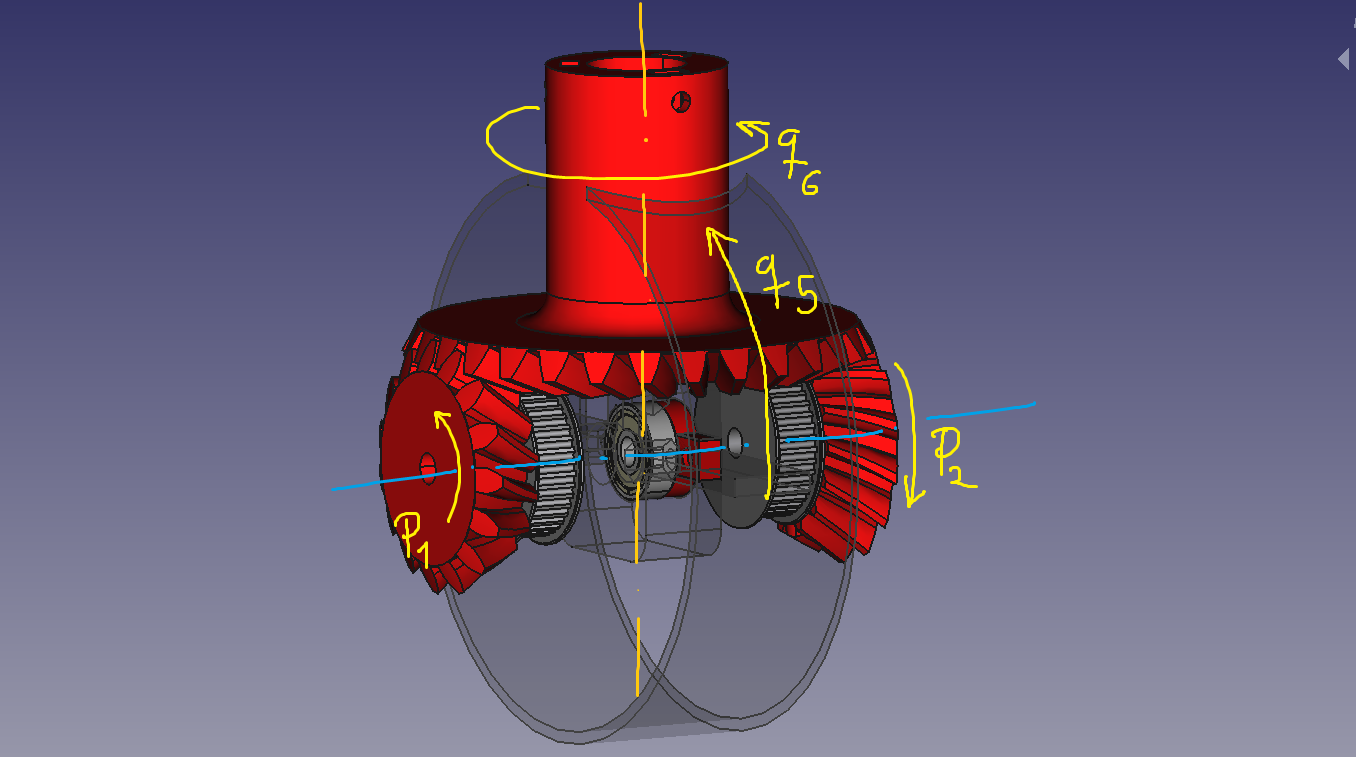

I couldn’t help myself and have been thinking about this.

I think the solution is as follows if we take into account the following sign convention for rotations:

p1 represents the angle rotated by pinion 1.

p2 represents the angle rotated by pinion 2.

q5 and q6 refer to the angles of joints 5 and 6 respectively.I think these equations are correct:

q5 = (p1-p2)/2

q6 = r*(p1+p2)/2

r = pinion teeths / crown wheel teethsI have obtained these equations by an empirical analysis of the problem and not by analyzing in depth the theory of the mechanism, so I could be wrong.

I hope it helps!

-

This reply was modified 3 years, 9 months ago by

-

AuthorPosts