Forum Replies Created

-

AuthorPosts

-

Ok. We did about infinite attempts to assemble it, but with a little help of Angel, it was easier that it seemed 😉

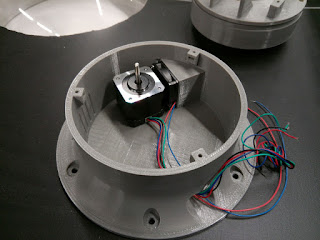

First we take out the eight screws that come with the articulation two stepper, the upper one. Four large cone headed screws for get the stepper parts joined, and four cylindrical head screws in the front that fix the gear block.After that we slide the stepper + gear block in the central slot, and fix the stepper with four 3×30 cylindrical head screws by the back.

Tip: it will be useful for you setting the stepper and routing the wires so they go to the right or to the left of the two lower steppers. Its not a good idea routing them vertically between the two lower steppers.

Now you can set in their position and fix the other two steppers + gear box by the back in the same way.

The more difficult part for us was fixing the steppers from the front after you have installed the Art2BodyACover1_01 ;piece. For that you need 8 screws that are shorter, something like 3×27 and two more indeed shorter than that. We trimmed them from the 3×30 screws. We experiment a lot of issues trying to get the screws enter in the stepper threads as straight as possible, and some of the screws threads get damaged, but at the end everything is fixed. (I hope)

I hope this is useful for anyone.Finally we start assembling the arm. First here is the group photo with almost all of the printed parts. It was a hard work. Thanks to any of the collaborators that contributed.

And here are some of the photos of the assembling of the body and first articulation. We discover that this is not the “natural” assembling order because we will have some difficulties conducting the wires from the upper articulations to the base. But we will deal with that…

Perhaps the more time consumer step was the assembling of the three geared motors inside the first articulation body.

Do you still have some control PCB’s. I will need one.

Thanks -

AuthorPosts